TURNS TEXTILE WASTE INTO VALUE

ReThinking the Textile Industry

Over 90 million tons of textile waste are generated every year, much of it burned or dumped. Today, industrial recycling is mainly done in two ways:

Mechanical recycling: Traditionally producing short fibres used for downcycling. Advances in spinning now allows yarn production, but only when 50–80% virgin fibre is added.

Chemical recycling: Breaks down fibres into new materials such as viscose or lyocell. A process requiring chemicals, water, and energy.

Both methods have their place, but challenges remain, especially in creating high-quality fibres from 100% recycled material.

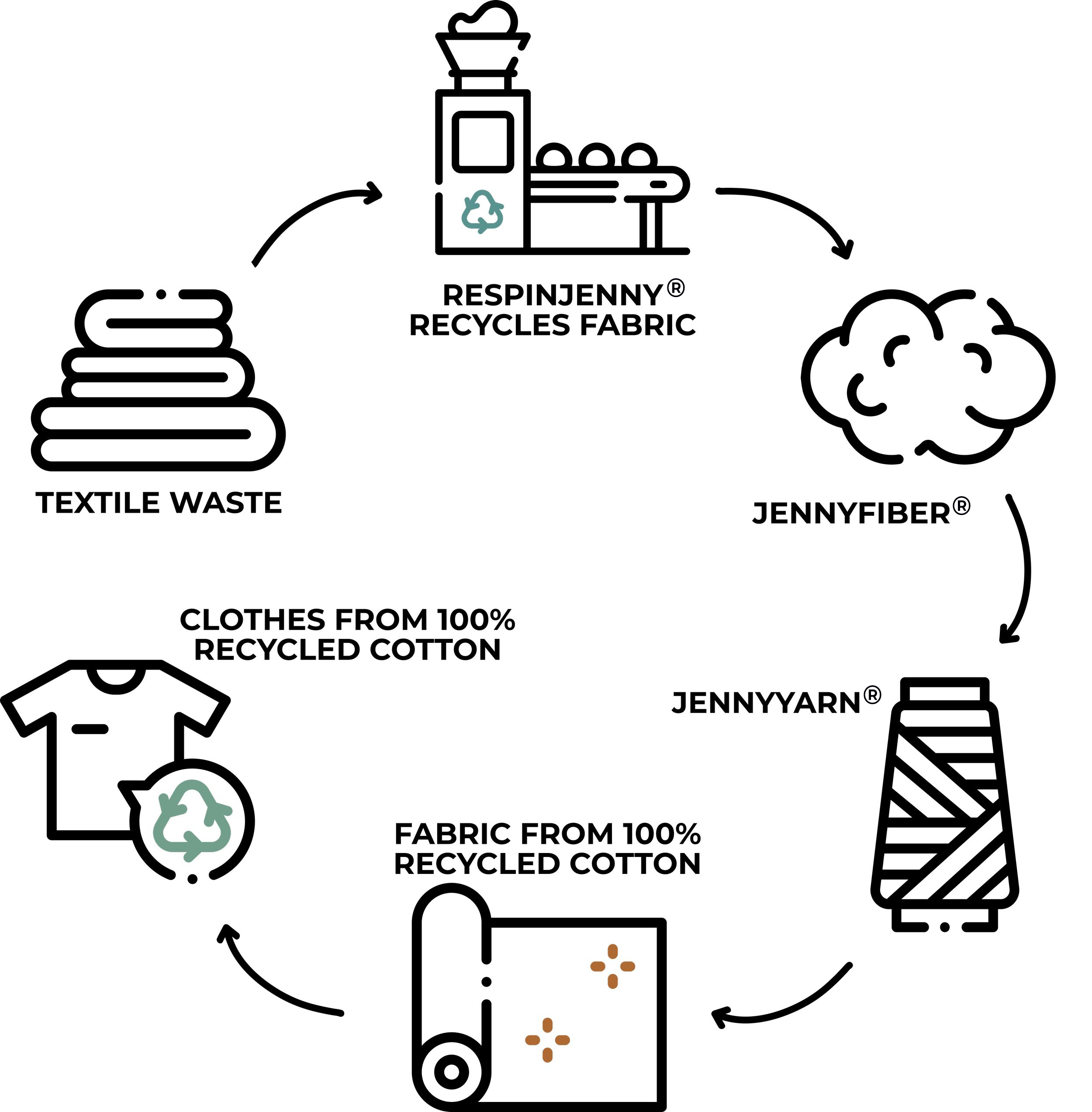

This is where ReSpin AB steps in, bringing a new approach that redefines what’s possible in textile recycling. Our technology transforms textile waste into JennyFiber®, recycled fibres with true spinning quality and JennyYarn®, enabling fabrics and ultimately new products. A complete circular journey, from waste back to value.

RespinJenny - Transforming Textile Recycling

RespinJenny® is a modular, fully automated machine that gently processes a variety of textiles into long, high-quality fibres, ready to be spun into new yarn without any virgin input.

With our quality labels JennyFiber® and JennyYarn®, RespinJenny customers can turn waste from a cost into a premium raw material and a revenue. They can differentiate their products, secure better prices, and give consumers a trusted quality mark, a guarantee the fibre was processed by RespinJenny.

Why invest in a RespinJenny?

Proven innovation: Patented, award-winning recycling technology with global scalability

Market-ready: Positioned to serve a fast-growing demand for circular materials

Regulatory momentum: EU legislation is accelerating industry-wide adoption

Measurable impact: Enables real reductions in resource use and emissions

Why ReSpin is a Gamechanger?

True Local Circularity

Repurposing fabric waste directly at the source, close to the cutting table, creating 100% recycled fibre.

Swedish Innovation

Elevating mechanical recycling to new heights with RespinJenny®; a patented, scalable solution setting the benchmark for premium fibre production.

Proven Sustainability Impact

Every kilo of fibre recycled reduces CO₂ emissions and resource extraction – with no water, no chemicals and minimal energy use.

Scaling Circularity in Textiles

ReSpin’s mission is to accelerate the shift toward sustainable textile production by closing the material loop, transforming textile waste into high-quality fibres and yarns with no water, no chemicals, and minimal energy use.

Our goal is clear: within the next decade, significantly reduce the industry’s reliance on virgin fibres. Achieving this requires ReSpin’s patented mechanical recycling technology to be implemented across textile factories worldwide.

As regulatory pressure builds, particularly within the EU, demand for verified recycled fibres will surge. The EU’s circularity directives are creating a rapidly growing market for scalable, low-impact solutions.

With proven innovation, commercial value, and future-proof performance, ReSpin is uniquely positioned to lead this transformation.

Award-Winning Innovation

“With drive and a clear vision, Åsa Strandberg is changing an industry with an innovative and patented process for the recycling of cotton textiles”

In 2024, RespinJenny received Sweden’s most prestigious innovation award – the SKAPA Prize – for redefining what’s possible in textile recycling. With patents granted in Sweden and Europe, our breakthrough technology is ready for global impact.

NEWS

Recycling Method

At ReSpin, we focus on keeping textiles in use for as long as possible. Today, our technology primarily processes sewing waste collected directly from the cutting table, transforming it into high-quality recycled fiber. As sorting and handling of discarded garments improve, RespinJenny can also be applied to post-consumer textiles.

By tackling waste at multiple stages of the value chain, we help manufacturers unlock new value, reduce resource dependency, and build a textile industry ready for the future.

RespinJenny, our machine that recycles high-quality fibres, enables the production of 100% recycled yarn sourced from sewing waste – 15 million tons annually. Our technology promotes sustainability while paving the way for new business models.

– Åsa Strandberg, founder ReSpin

Market Demand for

Sustainability Transformation

Did you know the textile industry is responsible for around 10% of global emissions, more than aviation and shipping combined?

Even before garments reach the store, fabric waste equivalent to every 4th–5th item is discarded during production. Add to those clothes worn only a handful of times before being thrown away, and the scale of the challenge becomes clear.

Change is possible – discover how smarter choices and advanced recycling can transform the industry.